Industry New

Automatic Hose Cutting Machine vs Manual Cutter

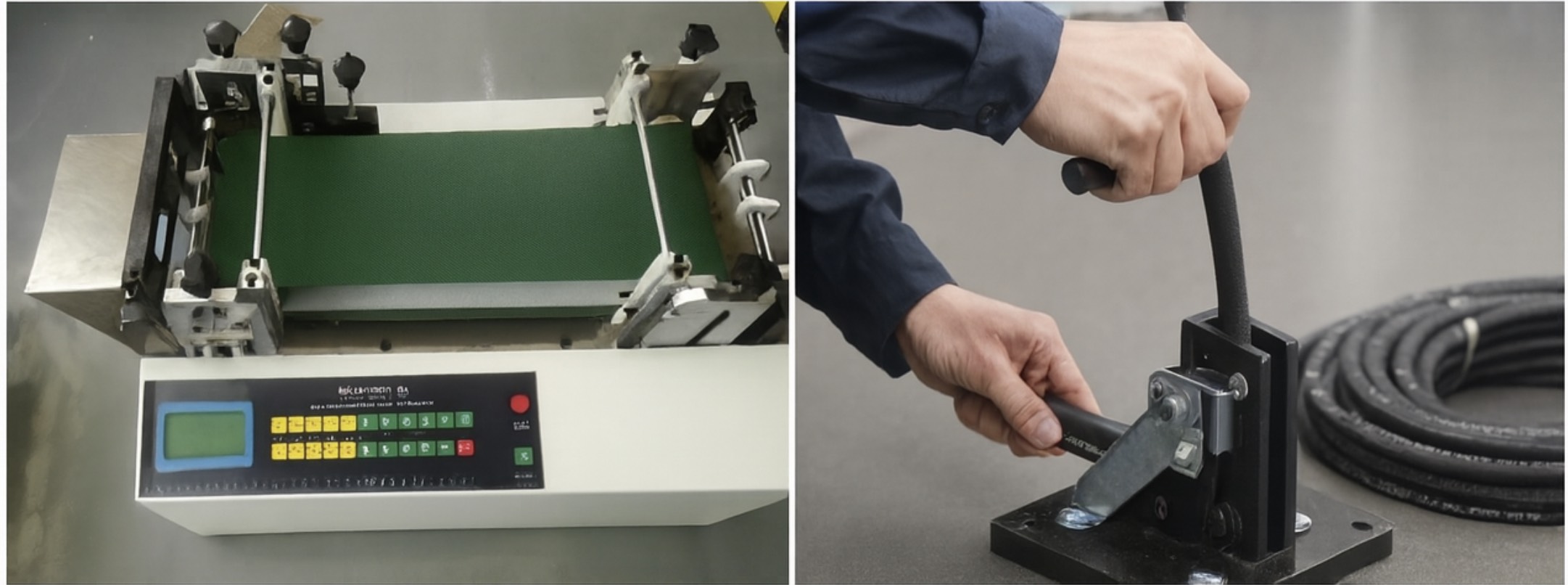

Automatic Hose Cutting Machine vs Manual Cutter – Which Fits Your Factory?

Introduction: The Modern Challenge of Industrial Hose Cutting

In today’s competitive manufacturing world, precision and productivity go hand-in-hand. Choosing between an Automatic Hose Cutting Machine vs Manual Cutter can significantly impact your factory’s efficiency, labor costs, and output quality. As automation becomes the backbone of modern production lines, understanding the trade-offs between manual and automatic cutting is crucial.

Industrial hoses—used in hydraulic, pneumatic, and fuel systems—require exact lengths and smooth edges. A slight deviation in measurement can lead to leaks, reduced performance, or even equipment failure. Therefore, selecting the right cutting system is more than a matter of convenience—it’s about long-term profitability and safety.

Understanding the Basics: What Are Hose Cutting Machines?

What Is an Automatic Hose Cutting Machine?

An automatic hose cutting machine is a computer-controlled system designed to cut hoses to specific lengths with precision. It uses sensors, servomotors, and programmable logic controllers (PLCs) to automate the entire process—from measuring to cutting. These machines often include high-speed blades, material feeders, and optional marking or coiling systems.

They’re ideal for medium to large-scale factories producing hoses in bulk, ensuring uniformity and speed. Some advanced models even feature touchscreen controls, auto-feed mechanisms, and integrated dust extraction systems for cleaner operations.

What Is a Manual Hose Cutter?

A manual hose cutter, on the other hand, relies entirely on human effort. Operators measure the hose manually, align it on a cutting surface, and slice it using a lever or rotary blade. While simple and inexpensive, manual cutters depend heavily on operator skill, which introduces potential for inconsistency and fatigue.

Key Differences Between Automatic and Manual Hose Cutters

Efficiency and Cutting Speed

Automatic machines can process dozens or even hundreds of cuts per minute, depending on the hose material and diameter. Manual cutters, however, are limited by human speed and endurance, making them better suited for small batches.

Accuracy and Consistency of Cuts

Automation ensures repeatability—each hose segment matches the programmed specification. Manual methods often result in slight variations, leading to waste or assembly issues later.

Labor Requirements and Skill Levels

Automatic systems minimize human intervention. Once programmed, they can operate continuously with minimal supervision. Manual cutters require constant attention, increasing labor costs over time.

Maintenance and Operational Costs

While automatic machines demand periodic calibration and maintenance, they generally reduce long-term costs by minimizing waste and rework. Manual systems have low maintenance but higher labor dependency.

Safety and Ergonomics in the Workplace

Automatic cutters include safety guards, emergency stops, and motion sensors. Manual cutters pose higher injury risks due to repetitive strain and blade handling.

Advantages of Using an Automatic Hose Cutting Machine

Precision and Repeatability in Production

Every cut made by an automatic system adheres to digital measurements, ensuring consistent product quality across all batches.

Time-Saving and High Output Efficiency

Automated feeders and programmable cutting lengths drastically reduce setup and changeover times, increasing daily throughput.

Smart Features and Automation Benefits

Modern automatic cutters integrate with IoT systems, allowing data logging, remote monitoring, and predictive maintenance.

Cost Efficiency Over the Long Term

Despite higher upfront costs, automation pays for itself through reduced labor expenses, material savings, and faster ROI.

Limitations of Automatic Hose Cutters

Initial Investment Cost

The primary drawback is the upfront cost, which can be 5–10 times that of a manual setup. However, financing or leasing options can ease this burden.

Complexity of Setup and Training

Operators need technical knowledge for calibration and maintenance. However, most manufacturers now offer user-friendly touchscreens and tutorials.

Advantages of Manual Hose Cutters

Lower Initial Cost and Simple Operation

Manual cutters are cost-effective for small shops or workshops handling diverse hose types and lengths.

Flexibility for Small-Scale or Custom Work

If your business handles short production runs or frequent specification changes, manual cutters offer adaptability without complex setup.

Limitations of Manual Cutters

Inconsistency and Operator Fatigue

As manual cutting relies on human effort, fatigue and error can lead to uneven cuts or quality issues over time.

Lower Throughput and Time Constraints

Manual cutters slow down production during high-volume demands, limiting factory scalability.

Cost Comparison: Automatic vs Manual

Upfront and Ongoing Costs Breakdown

| Feature | Automatic Cutter | Manual Cutter |

|---|---|---|

| Initial Cost | High | Low |

| Labor Cost | Minimal | High |

| Maintenance | Moderate | Low |

| Energy Use | Moderate | None |

| Waste Reduction | Excellent | Average |

| Productivity | High | Low |

ROI and Payback Period Analysis

Factories switching to automatic machines often see ROI within 12–24 months due to savings in labor and reduced material waste.

Which Machine Fits Your Factory Best? (Decision Matrix)

For Small Workshops and Low Volume Needs

If your output is under 100 hoses per day and customization is frequent, a manual cutter is sufficient.

For Large-Scale Industrial Manufacturing

Factories producing 500+ hoses daily benefit enormously from automation, achieving better consistency and cost control.

Environmental and Energy Considerations

Automatic machines are increasingly energy-efficient, using programmable sleep modes and optimized motor drives. Manual cutters, while low-energy, produce more material waste due to uneven cuts.

Future Trends in Hose Cutting Technology

Integration with Industry 4.0 and IoT Systems

Next-generation machines integrate sensors and cloud monitoring, enabling predictive maintenance and real-time performance analytics.

Expert Recommendations for Selecting the Right Cutter

-

Assess your production volume.

-

Calculate total cost of ownership.

-

Consider automation readiness.

-

Choose a trusted supplier with after-sales support and training.

(For more details, visit Sunhose’s Hose Cutting Solutions for real-world examples.)

FAQs About Hose Cutting Machines

1. Can a manual cutter match automatic cutting accuracy?

Not consistently. Manual cuts depend on operator skill, while automatic systems ensure precision every time.

2. Are automatic hose cutters hard to maintain?

No. Most models include self-diagnostic tools and easy calibration features.

3. How long does it take to recover the investment?

Typically 1–2 years, depending on production volume and labor savings.

4. Can I cut different hose materials with one machine?

Yes, most automatic machines support rubber, PVC, and PTFE hoses with adjustable parameters.

5. What’s the best choice for startups?

Start small with a manual cutter, then upgrade to an automatic machine as demand grows.

6. Do automatic hose cutters support remote monitoring?

Advanced models with IoT integration do—offering live status tracking and maintenance alerts.

Conclusion: Finding the Right Balance Between Cost, Output, and Automation

The choice between an Automatic Hose Cutting Machine vs Manual Cutter depends on your production scale, labor costs, and long-term goals. If you prioritize precision, speed, and scalability, automation is the smarter investment. However, for small, flexible operations, manual cutters still hold value due to their simplicity and affordability.

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Sunhose

Phone: +8618056044070

Tel: +8618056044070

Email: info@sino-hose.com

Add: New & Hi-Tech.Industrial Development Zone,Anhui,China